Description

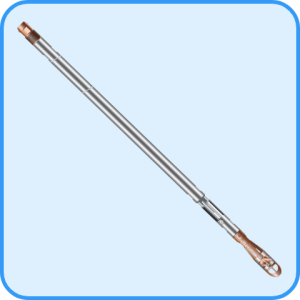

Roller Centralizer

A roller centralizer is a mechanical tool used in production logging operations to keep a production logging tool string centered within a wellbore. The tool consists of a series of rollers attached to a central body, which is mounted on the logging tool string.

As the tool string is lowered or raised within the wellbore, the rollers rotate and make contact with the inside of the wellbore wall. The rotation of the rollers helps to reduce friction between the tool string and the wellbore, allowing the tool string to move more smoothly and accurately.

In addition to reducing friction, roller centralizers also help to maintain the vertical alignment of the tool string within the wellbore. This is important because an off-center tool string can produce inaccurate or inconsistent data during production logging operations.

Roller centralizers come in a variety of sizes and configurations to accommodate different wellbore diameters and tool string designs.

Features:

| General Specs | Centralizer |

| Length | 31.13″ |

| Pressure rate | 18,000 psi |

| Temperature | 350 deg F |

| Material type | Sour Services Ready |

| Connectivity | Go connector |

| Operation range (Min. restriction – Max casing) |

1-11/16” to 7-5/8” 24# casing. A different set of links can expand the diameter to necessary dimensions (13-13/8” max) |

| Max tension | 18,000 lbf |

Reviews

There are no reviews yet.